skidmore passivhaus was recently featured in the wall street journal.

Posts Tagged ‘jeff stern’

wall street journal

March 31, 2015form factor and passivhaus

September 23, 2014It is well known that compactness is an important aspect of a well designed and cost effective Passivhaus as it has a considerable impact on the overall heat demand. Having now modeled a number of projects in PHPP (Passive House Planning Package), I decided to do a quick comparison of the ratio of envelope to floor area (known as the form factor) as well as the average R-value of the entire envelope. Here are a few examples:

Emerson

envelope to treated floor area: 3.8

average R-value: 39.4

_

Skidmore

envelope to treated floor area: 3.7

average R-value: 29.7

_

18th Ave Residence

envelope to treated floor area: 3.2

average R-value: 24.1

_

Haig Haus

envelope to treated floor area: 2.7

average R-value: 25.9

_

Ankeny Apts

envelope to treated floor area: 1.5

average R-value: 19.7

While there are many variables at play that make each project distinct, it is clear that form factor has a huge impact. Remember boxy can be beautiful!

smart and simple

February 1, 2014brian libby of portland architecture writes about his visit to the skidmore passivhaus:

more news coming soon!

thermos

January 2, 2014we’re excited to share that skidmore passivhaus is featured in the january 2014 issue of portland monthly magazine!

pick it up at your nearest newsstand.

you can also see an excerpt here:

if you want more info visit us at:

ph certified

September 28, 2013we recently were notified by PHIUS that skidmore passivhaus is officially a certified Passive House (PHIUS +).

we look forward to sharing the knowledge gained on our first completed passivhaus and helping others create well designed high performance low load buildings.

cool green

July 23, 2013more we now have a little patch of green lawn and some rusty planters to go with our deck. summer is here.

with the amount of high shgc glass on our south facade, it would be easy to overheat without proper shading.

on the hottest days, we simply close our exterior shades to block unwanted solar radiation before it hits the glass. the ability to fully control the shades means we can optimize the amount of gain or shade we are getting depending on the daily conditions.

the shades can be tilted to allow views out while still blocking the sun. the cost of the shades was offset by the elimination of cooling equipment and the cost of the energy to operate it.

the exterior shades combined with the exceptional insulation and thermal mass has kept our house exceptionally cool and comfortable without any air conditioning.

more detail to follow. check back soon.

fast forward

May 20, 2013we’ve been too busy to post for quite awhile, but work has been progressing nicely on the skidmore house. here’s a quick look around:

we hope to be putting the final touches on in the next few weeks. lots of catching up to do. check back soon for more on this project and others.

suck and blow

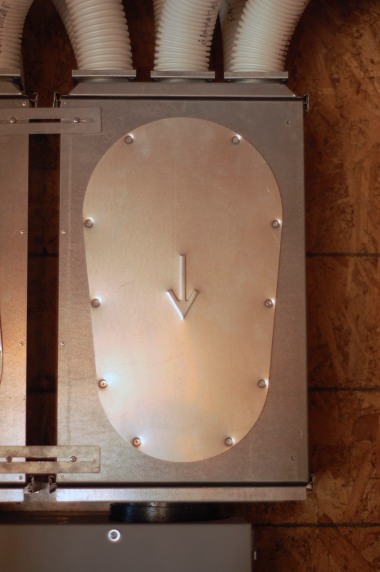

March 27, 2013rough-in work has wrapped up on skidmore passivhaus and it’s time to look at a few of the features under the hood. this new airtight home (or shall we say leak-free) is equipped with mechanical lungs.

we chose the PH certified zehnder comfoair 200 hrv, capable of producing up to 125 cfm of continuous ventilation. this project requires about 70 cfm (60% setting) to achieve .31 air changes per hour (or roughly 1 air change every 3 hours).

the 3″ flexible ductwork is a double-walled proprietary system called comfotube made by zehnder. very easy and fast to install. the goal is to keep the runs as short and straight as possible.

the round ceiling rough-in boxes are used for either supply or exhaust air. either 1 tube or 2 tubes are connected depending on the cfm requirements. exhausts are located in the bathrooms (20 cfm continuous) and kitchen (30 cfm continuous). we have 3 exhaust locations – each with 2 tubes. there are 4 supply locations.

supply air is typically provided at the ceilings but we have a low supply register in the double height living room.

the tubing terminates in the ceiling of the mechanical room. 6 supply tubes and 6 exhaust tubes. manifolds gather the supply and exhaust tubes respectively and connect them to the unit.

exhaust air flows through the machine, the heat is captured in the core, and the air is expelled to the outside.

fresh air is brought into the machine from the exterior, and warmed by the heat captured from the outgoing air. the zehnder is about 92% efficient and uses just 7.1 watts / cfm.

the fresh air supply and exhaust are ducted in well insulated metal ductwork from the bottom of the unit to the exterior. the fresh air supply is located high on the exterior wall with the exhaust about 10′ below. the duct penetrations were carefully air sealed to the plywood air-barrier. this unit also requires a condensate drain that we’ve tied with an air gap into the kitchen waste pipe.

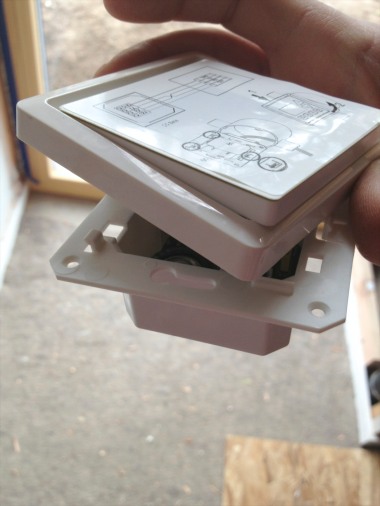

the main controller will be located in the kitchen, providing the ability to boost the ventilation rate temporarily to 35 cfm while cooking. each bathroom will have a timed switch to boost the rate to 24 cfm if needed after a shower. we also conveniently have an operable window located in the kitchen and both showers.

thanks to IM Plumbing for help with the installation, and to Matt Grove from Zehnder for help with the design.

sheetrock has wrapped up and painting has begun. check back soon for more.

blow

February 19, 2013stained cedar siding

February 10, 2013siding work has mostly wrapped up. the vertical siding is installed on rainscreen over rigid exterior insulation. see this past post for more info on the assembly.

here’s a first look at the siding pretty much completed.

the siding is off the shelf 1×6 channel made from tight knot cedar. it’s stained with 1 coat of olympic semi-transparent stain in ebony.

the large south windows (and doors) have exterior motorized aluminum sun shades supplied by hella. the siding has been detailed to allow the shades to stack in recessed pockets. in this photo the shades are down about 9 inches and just visible on the 2 living room units (lift / slide door and fixed upper unit). more on the shading later.

the “breezeway” features a south facing door / window with a wood canopy (to be painted black) topped with clear tempered glass.

the entry door at left features acid etched glass for privacy and has a smooth accent panel adjacent that will be painted a deep red. the wood canopy will painted black and features a simple galvanized metal pan roof. steel rod will be used to hang the canopy from a bracket mounted to the wall above. a mahogany deck will eventually complete the front porch.

the north street facade also features a narrow smooth accent panel that will be painted with the same deep red. the same siding runs horizontally to form an accent between floors.

check back soon for more.