after more than 2 years living in skidmore passivhaus, i’m frequently asked is it working? let’s take a look at the numbers from the last year:

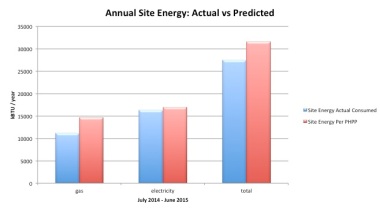

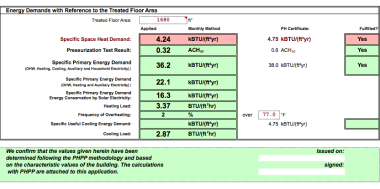

it’s interesting to compare our actual annual consumption to the predicted consumption per the PHPP model. this project was modeled in PHPP 2007, and there has been some criticism in the passive house community suggesting that the German default values for electrical consumption built into PHPP are far too low for the US culture. (PHIUS has gone so far as to radically change the default values for electrical consumption). given the data on our project, i’m not so sure there is a problem.

occupant behavior of course plays a significant role in energy consumption, and there are a number of conditions to note for this building. PHPP assumes 4 occupants for a house of this size, when in reality there are only 2 of us (plus 1 dog and 2 cats) which should result in lower overall energy consumption. with fewer occupants, there will be lower internal gains which presumably would increase slightly the heating demand and heat load. Because we both work from home much of the week with computers and other devices running all day, it could be assumed that while there are only 2 of us, our consumption includes both home and work and would therefore be higher. I also should note (somewhat sheepishly) that we have 3 cables boxes that stay on all the time, including one DVR, which draw a steady amount of electricity and generate some heat. This is all somewhat anecdotal, but it shows the inherent complexity in accurately predicting energy consumption.

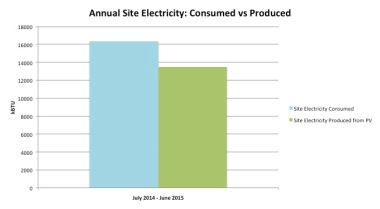

an annual summary of our site electricity consumption and site energy production (from our roof mounted 4.32 kW array) shows that we generated 82% of the electricity we consumed.

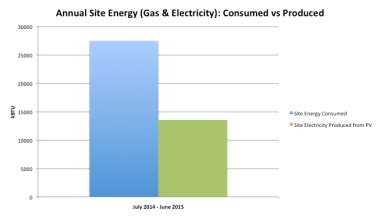

an annual summary of our site energy consumption (gas and electric) and site energy production shows that we generated 49% of the total energy we consumed.

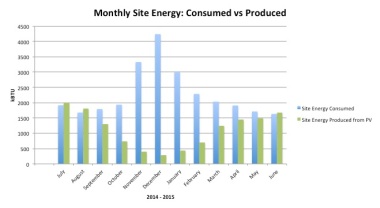

a monthly summary of our site energy consumption (gas and electric) and site energy production (from our roof mounted 4.32 kW array) shows the large deficit during the winter months as expected. more efficient equipment for our space heat and hot water would certainly help to offset some of this deficit. while a larger PV array would get us closer to net zero on an annual basis, it wouldn’t solve this deficit and demonstrates one of the problems with an approach that focuses solely on annual net zero energy. elrond burrell has written an excellent blog post covering this topic.

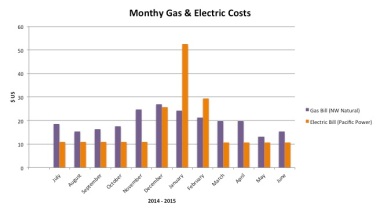

a monthly summary of our annual gas and electric bills demonstrates our consistently low monthly utility costs. our average monthly cost for both gas and electricity over the last year was $36.53.

note that for most of the year we pay our electricity provider the minimum monthly charge even though we are generating more electricity than we are using. our only gas appliance is our hot water heater, and a significant portion of our small monthly gas bill is for fees and taxes regardless of our consumption. if we were to change our gas water heater to electric even without a change in energy consumption, our monthly utility cost would be even lower by eliminating the minimum gas charges.

aside from reducing our CO2 emissions and our consistently tiny utility bills, we’re staying extremely comfortable year round – warm in the winter while barely using our heating system, and cool in the summer without any air conditioning. so the answer is unequivocally yes, it is definitely working.